PROJECT INTERSECT BY LEXUS

DESIGN WONDERWALL

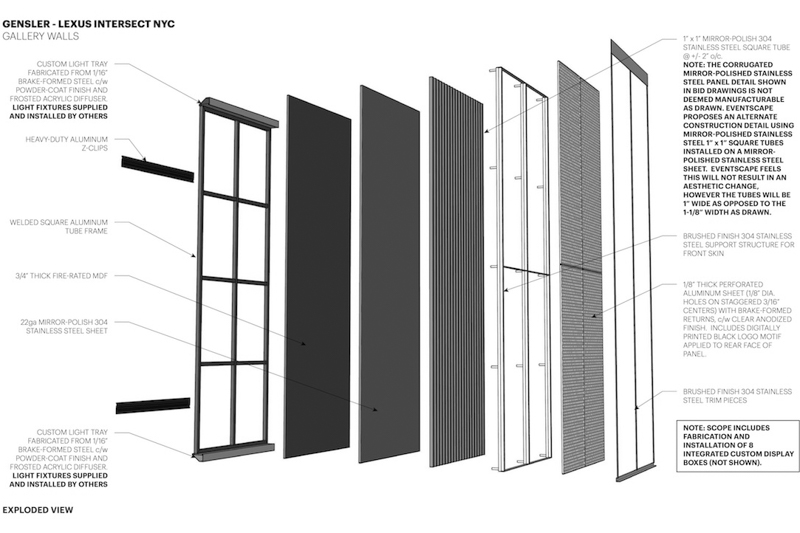

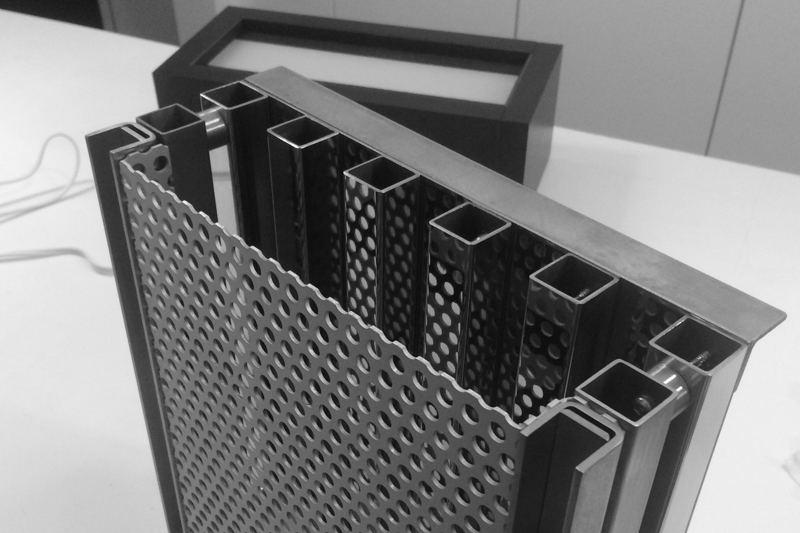

ARCHITECT OF RECORD GENSLER

GENERAL CONTRACTOR AMERICONHITT

PHOTOGRAPHY INTERSECT BY LEXUS – NYC

VIP GALLERY BUILT BY EVENTSCAPE SEPTEMBER, 2017

INTERSECT BY LEXUS OPENS ITS THIRD GLOBAL LOCATION IN NEW YORK CITY

A New Lifestyle Hub, INTERSECT Merges Innovative Programming, Culinary Creativity and Masterful Design for an Immersive Cultural Experience

On November 15, 2018, INTERSECT BY LEXUS – NYC – a unique cultural space where ideas and people converge – opened its third global location in New York City. Following successful launches in Tokyo and Dubai, INTERSECT BY LEXUS will live in the heart of the vibrant Meatpacking District and continue the brand’s commitment to supporting innovation on a local, national and global level.

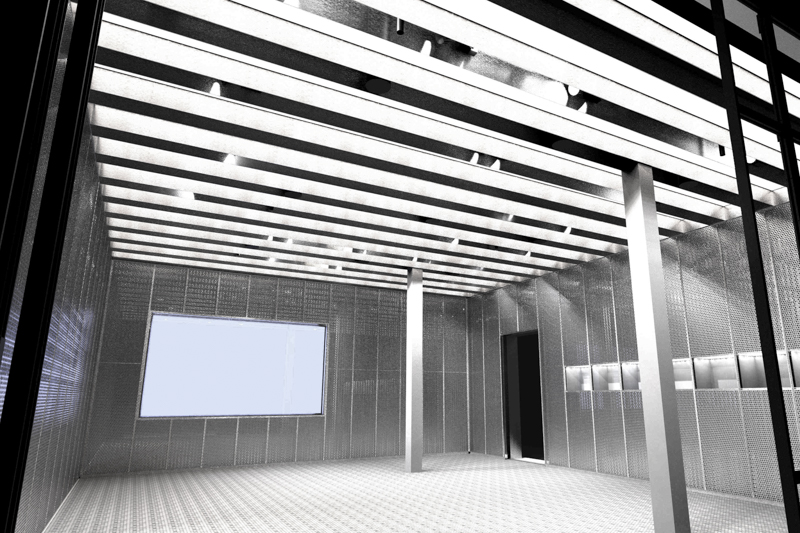

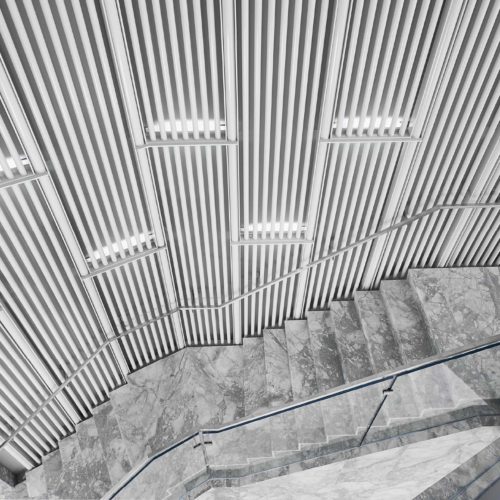

Crafted by world-renowned interior designer Masamichi Katayama of Wonderwall, who also led design in Tokyo and Dubai, the 16,500 square foot, three story Manhattan space will be the largest of the three properties, with unique elements and experiences that evolve with each distinct floor. The street level will be anchored by the Café area, the CRAFTED FOR LEXUS retail area and a Public Gallery space, which will feature everything from product concepts to custom exhibitions and installations. The inaugural full-service Restaurant at INTERSECT BY LEXUS – NYC and Cocktail Bar and Lounge will be located on the second floor. The Café, Restaurant, and Cocktail Bar and Lounge will be managed by Union Square Hospitality Group. Finally, the third floor Private Gallery rounds out the space and will transform for a multitude of culturally relevant programming concepts such as: full immersion events, art installations, film screenings, panels, performances and other inviting experiences.

INTERSECT will call upon visionaries to collaborate on experiential programming that engages with the building, community and five core pillars – hospitality, food, design, entertainment and technology. Each program will intersect facets of culture on multiple levels and deliver creative, exceptional moments to the city and beyond.

“The collaborative nature of New York City makes it a natural choice for the next adaptation of INTERSECT,” says Kirk Edmondson, General Manager of INTERSECT BY LEXUS – NYC. “We anticipate the cornerstones of the city will come to life within the space and become a hub where New Yorkers gather and share ideas. The unique space promotes curiosity and creativity that will inspire the next generation of innovators.”

At its heart, INTERSECT is a manifestation of Omotenashi, a brand core value characterized by an unwavering commitment to exceptional hospitality. The spirit of Omotenashi is one of absolute consideration to ensure that INTERSECT and its staff are completely in tune with and can anticipate guests’ needs before they even arise. This steadfast dedication to creating a truly exceptional experience is what drives every facet of INTERSECT, from conceptualization to actualization of every element within the New York City location.

RESTAURANT

A destination within a destination, the restaurant at INTERSECT will offer fine dining to provide patrons with world-class cuisine in a refined yet informal atmosphere. A rotating Global Chefs-in-Residence program will allow the restaurant to introduce a new dining concept from a different chef every four to six months, each of whom will be selected in collaboration with Danny Meyer’s acclaimed Union Square Hospitality Group.

“In many ways this is a dream collaboration as Lexus shares our commitment to hospitality, excellence and innovation, and INTERSECT is the perfect canvas for experimentation,” says Ron Parker, Chief Operating Officer of Union Square Hospitality Group. “When presented with the opportunity to search the globe for culinary innovators, we couldn’t wait to collaborate with some of the most exciting and inventive chefs that live to create positive and uplifting experiences for all guests.”

Hosting innovative and emerging culinary talent from across the globe is a direct reflection of INTERSECT’s commitment to supporting the creative community on an international scale. The restaurant will officially open with Chef Gregory Marchand who has built his culinary notoriety with Frenchie Restaurant in Paris and Frenchie Covent Garden in London. Chef Marchand will bring his Frenchie philosophy, which values quality in simplicity, to INTERSECT. His inspired menu will feature dishes rooted in French cuisine and transformed to infuse the flavors of the esteemed restaurants, chefs and countries he has come across throughout his career.

Dishes will include starters such as Fluke Carpaccio (citrus condiment, crispy quinoa), Foie Gras Terrine (smoked pastrami, cucumber, melba toast), Agnolotti (Smoked sunchoke, Piedmont hazelnut). Main dishes range from Duck (salsify, parsnip, sesame) to Halibut (grenobloise, brussel sprouts) as well as Beef (tenderloin, braised short rib, artichoke, olive-tamarind), Roasted Carrot (feta, tarragon, kumquat) and Scallops (bean ragu, chard pesto, sobresada). Desserts include a variety of options such as Mont Blanc Yuzu (chestnut cream, yuzu sorbet), Warm Chocolate Mousse (bacon ice cream, hazelnut), Tarte Tatin with cardamom cream and Banoffee (banana, dulce de leche, pecan).

Neighboring the dining room sits a Cocktail Bar and Lounge. The cocktail program will draw inspiration from the seasons, featuring signature creations as well as updated classics. A selection of cocktails includes The Intersect (gin, cappelletti, yuzu- honey, aquafaba, rose, vanilla cardamom almond milk), Pardon My Frenchie (aqua di cedro, pommeau, Earl Grey Tea, lemon verbena) and Smoked and Salted (bourbon, maple syrup, smoke & salt bitters). There will also be a thoughtful selection of beer and wine.

DESIGN

INTERSECT’s dedication to the brand’s Takumi craftsmanship – a quintessentially Japanese term translating roughly to “artisan”– resonates throughout the building’s design. Using this philosophy, Mr. Katayama has transformed the space into three distinct levels with corresponding personalities.

Like both of the previous locations, the new design-forward hub will contain signature elements inspired by INTERSECT’s global reach but that also reflect an authentic aesthetic of the surrounding city. Standout elements such as a wall display with over 1,200 miniature car models, a two-story art installation featuring historic Lexus vehicle parts and bamboo window screens inspired by the signature Lexus spindle grille are shared with the Tokyo and Dubai locations.

The first floor includes a black and white marble Café, a library wall, comfortable seating areas as well as subtle nods to the intersection of culture, conversation and design. Meanwhile, the Café’s under-the-counter Modbar brewing system enables conversation between the barista and guests. This approach contributes to the Omotenashi of INTERSECT.

At the top of the glass and steel staircase that leads up to the second floor sits a floating bridge that continues to the restaurant at INTERSECT and the Cocktail Bar and Lounge. In the restaurant guests are welcomed by an open-concept kitchen that allows diners to watch Chef, furthering the dedication to warmth and Omotenashi. Elegant herringbone patterned floors and a striking white marble countertop are complemented by a carefully curated library stretching against the west wall. The private dining room displays a spectacular Lindsey Adelman “Agnes” chandelier, as well as an art installation depicting a skyline that includes iconic buildings around the world. This custom piece from Ryu Itadani features over 30 New York City buildings and is inspired by the brand’s automotive heritage.

The Cocktail Bar and Lounge features a 360-degree bar that is crafted from black marble, stainless steel and the same leather used in the LFA supercar. The lounge is sleek yet inviting, with contemporary furniture using wood and leather materials, and includes a third extension of the curated library. The space showcases details such as Carbon Fiber countertops, another core material from the LFA, and an inlaid tile floor with a subtle repeating “L” pattern. Similarly to the Café, the bar creates an open atmosphere between servers and customer, a nod to the overarching social theme.

INTERSECT BY LEXUS – NYC is located at 412 West 14th Street New York, New York 10014. Starting in December 2018, the restaurant will serve lunch seven days a week from 11:30-3PM. Dinner will be available Sunday-Wednesday from 5PM-10PM and Thursday-Saturday from 5PM-11PM. The café is open from 7AM-7PM seven days a week. For more information on the space please visit www.Intersect-NYC.com.

ABOUT INTERSECT

INTERSECT BY LEXUS is a unique space in select global cities where people can experience the ethos of the Lexus lifestyle. Opening in New York City on November 15, 2018, guests will be able to engage with Lexus through events, activities, food and culture. The design of the space was developed by Masamichi Katayama (Wonderwall Inc., the world-renowned Interior designer.) A destination within a destination, INTERSECT will offer a restaurant featuring a revolving global chef residency, allowing New Yorkers and world travelers to consistently embark upon a new gastronomic adventure. Through the vision of Lexus and Union Square Hospitality Group, INTERSECT’s restaurant will showcase handpicked top chefs from around the world. INTERSECT’s New York location joins the existing experiential venues in Tokyo and Dubai. Lexus also acknowledges the lead creative contributions and guidance of Inform Ventures in the creation of INTERSECT BY LEXUS – NYC in providing programming ideas for this space.

![3402-LEXUS GALLERY-INSTALL SEQUENCING BY EVENTSCAPE_REVA1[1] INTERSECT BY LEXUS](https://eventscape.com/wp-content/uploads/2019/01/3402-LEXUS-GALLERY-INSTALL-SEQUENCING-BY-EVENTSCAPE_REVA11-1.jpg)