PROJECT GTAA PASSENGER INFORMATION ZONE – PHASE TWO, PEARSON INTERNATIONAL AIRPORT, TORONTO, ON

DESIGN STANTEC

GENERAL CONTRACTOR T3 (ART GARDEN) ELLIS DON, T1 (ART STRATA) TORQUE BUILDERS

PHOTOGRAPHY STEVE TSAI

BUILT BY EVENTSCAPE, APRIL 2017

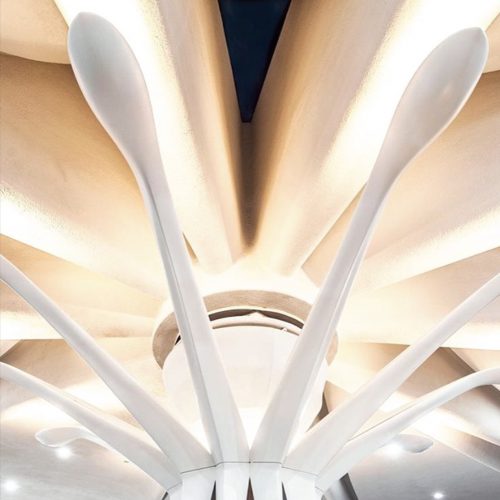

The second stage of the Greater Toronto Airport project for Eventscape was a continuation of passenger information zones in other areas of the airport — both before and after the customs gates. The design of the zones were continued throughout, based on the main large flower structure, desk and kiosks that were installed in Phase One. This included an additional nine stand-alone kiosks in two different sizes, three pylons and three smaller information desks. The information desks continued the style of the 22-foot long complex curved main desk but at a reduced size. The pylons and the kiosks were almost identical to the ones in the main information area. These were all built with steel and/or wood sub-frames and clad with formed curved solid surface and solid wood. Not only was the solid surface material able to be formed into the complex curve, it is an extremely durable, non-porous, anti-bacterial material. This resulted in elements that can easily withstand the high-traffic 24-hour use in one of North America’s busiest airport.

Unique Characteristics & Project Challenges:

Information Desk: A compact form, this six-foot-long information desk has a millwork substructure with curved, formed solid surface cladding and finished with a lacquered wood top. After reviewing with the information service staff, the transaction top and cantilever were designed and engineered for the best ergonomics. The base incorporated two lockable drawers and stainless steel grommet for wire management. The desk was built at lower counter height to accommodate both standing and seated attendants and finished with a stainless steel kick plate.

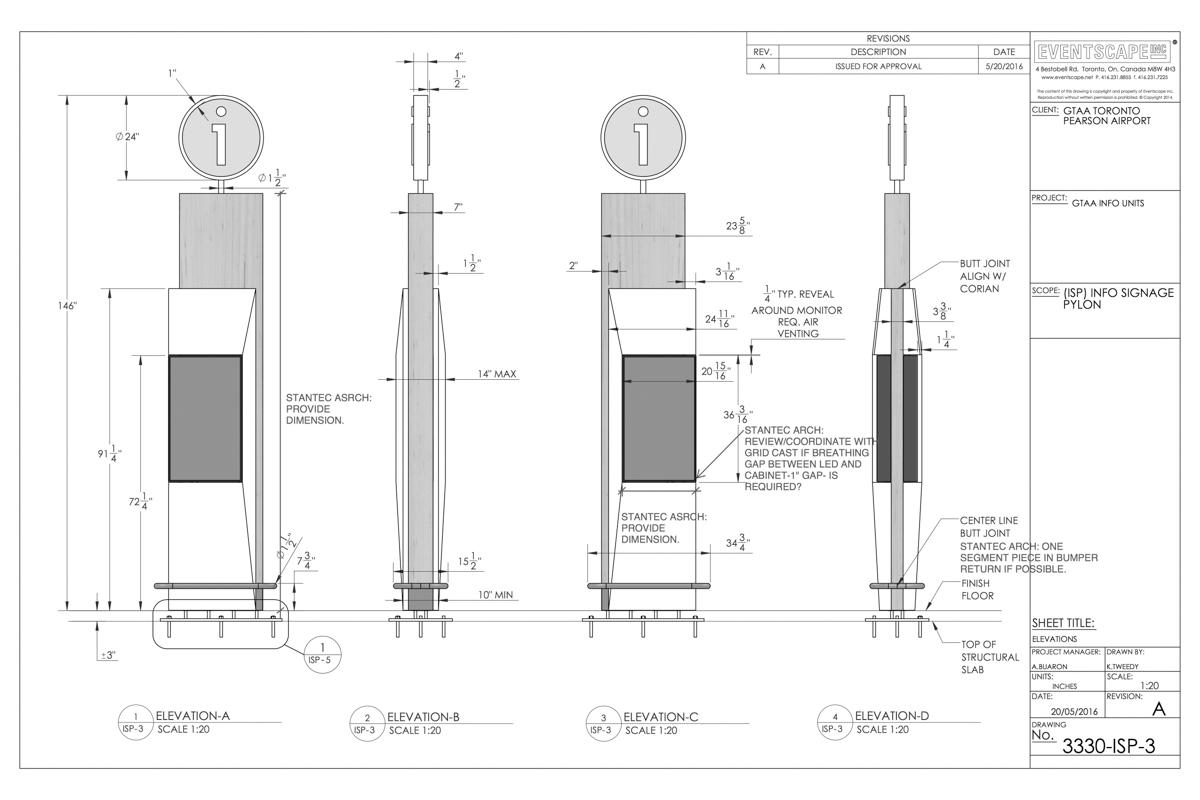

Pylon: The 14-foot high x 2-foot wide information pylon incorporates an interactive touch display of flight information for passengers to browse, along with a map of the airport. Three heights of the pylons were engineered and built to correspond to the installation locations —10, 12 and 14-feet high. The 2-foot high LED backlit “i” at the top of the pylon directs visitors to this zone. The pylon was built with a structural steel metal frame, wood veneer, angled solid surface finish and anchored to the structural slab below. A stainless steel bumper rail completed the bottom of the structure.

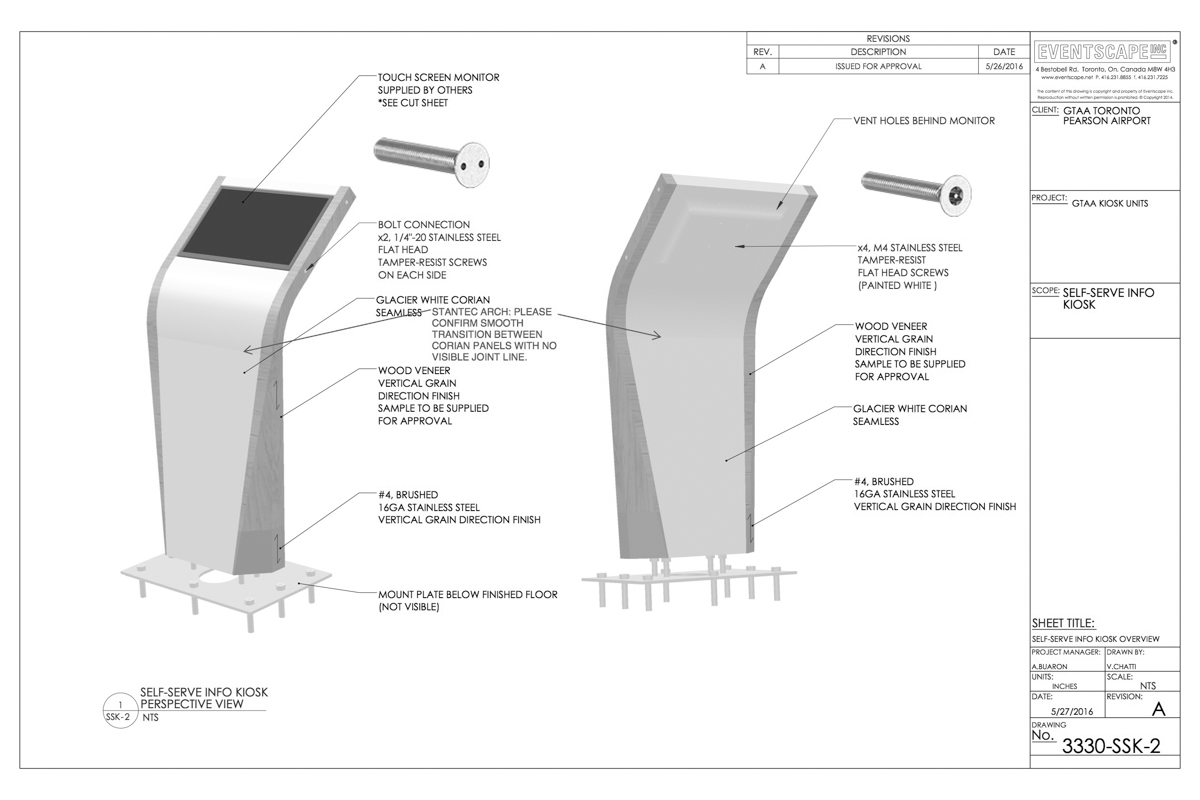

Kiosks: Similar in construction to the desk and pylon, with steel sub frame and wood and solid surface finish, the self-serve information kiosks are gently curved to give the perfect viewing angle for the integrated touch-screen monitor.Adjacent to the desk, there are three kiosks — 2 at standing height and one lower height, ADA compliant. A vacuum-formed solid surface back panel with ventilation holes houses the monitor. Security fasteners were used for assembly to allow access for maintenance. The wood end caps had a complicated geometric shape that was both curved and faceted. The digital fabrication team at Eventscape used CNC-cut high density tooling foam as the base and added carefully applied wood veneer laminate. After staining, a catalyzed lacquer sealer was applied to give an extremely durable finish for this high traffic area.

Eventscape’s engineers, designers, experienced fabricators and their ability to work in multiple materials provide architects with options and solutions to the challenges of both new builds and retrofitting existing spaces.