PROJECT ATRIUM SLEEVE, WASHINGTON, DC

ARCHITECT SHoP ARCHITECTS

INTERIOR DESIGN K&CO, PLISKIN ARCHITECTURE

GENERAL CONTRACTOR RAND CONSTRUCTION

AWARDS INTERIOR DESIGN BEST OF YEAR 2020, FINANCE/LAW OFFICE

PHOTOGRAPHY DAVID MITCHELL

BUILT BY EVENTSCAPE, NOVEMBER, 2018

Project Description:

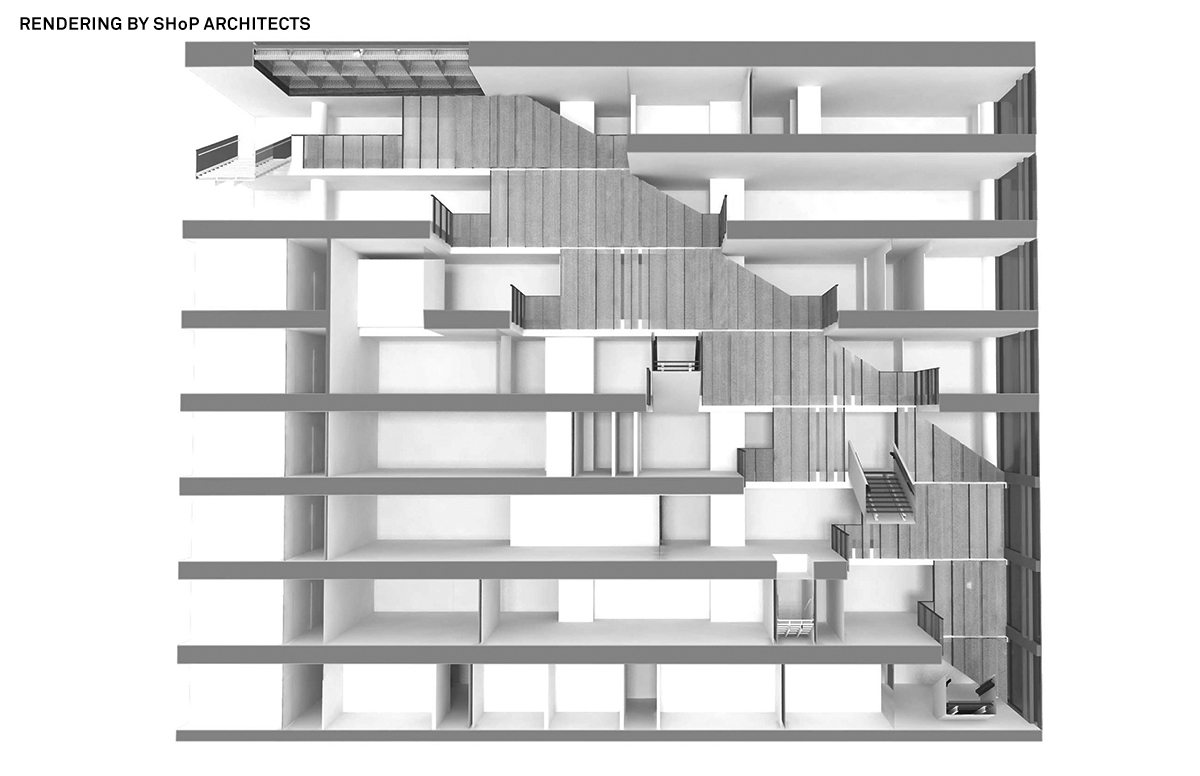

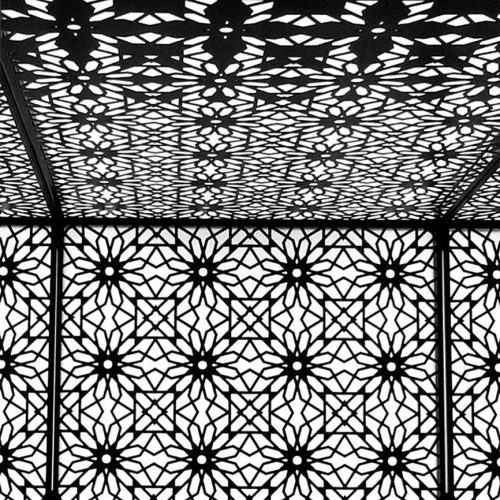

This 7-storey new build features a unique atrium space with staggered openings on each floor. SHoP Architects designed a custom structural sleeve barrier to surround each opening. Both practical and beautiful, it was built of over 238 decorative custom perforated Muntz metal screens, with 4800 square feet of walnut cladding elements and anodized, custom extruded guardrail caps. Eventscape was uniquely positioned to build this metal and millwork feature in-house as their engineering, detailing, fabrication and installation teams enabled the contractor to streamline the multiple partners on this feature to one and allowed for extremely tight tolerances.

Unique Characteristics & Project Challenges:

One of the first challenges of this project was how to maintain perfect alignment while engineering sufficient tight tolerances at this scale. During the initial design discussions, Eventscape hosted the interior design firm as well as the architects to view a full-sized mockup. This was used not only to finalize the metal finish but also to confirm that all the materials adjacent to the sleeve fit perfectly. Understanding the entire project and design intent meant that the team at Eventscape could suggest appropriate options. During this design planning stage, Eventscape’s team engineered a solution to ensure the sleeve was able to move and be installed independently of the base building.

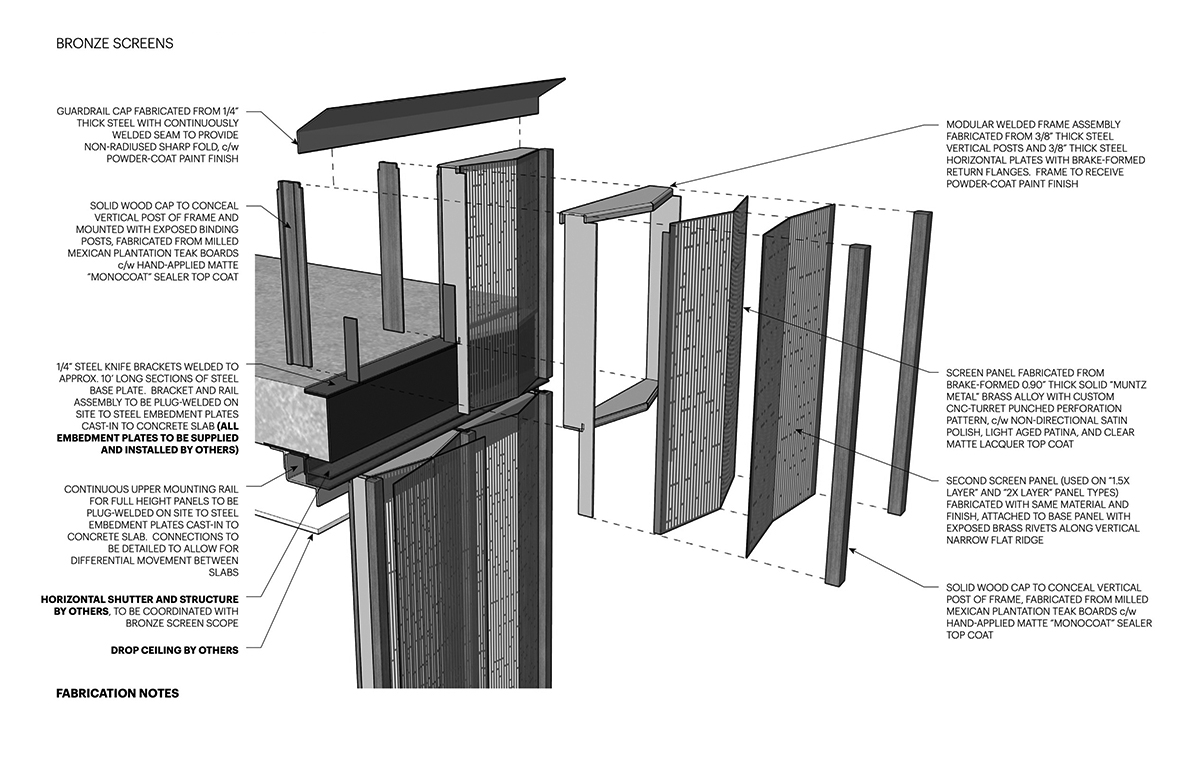

Some of the custom perforated Muntz metal screens were brake-formed with additional panels brake-formed using the reverse angle attached on the interior of the atrium opening. The screens began at the reception, continuing on each floor up to the ceiling where 38 perforated angled skylight panels complete the feature. Eventscape’s scope included all screen elements including structural mounting brackets, modular steel frames, walnut cladding elements and guardrail caps.

The Muntz panels required a 9-step process from initial engineering to laser cutting, polishing, and forming with a final patina finish. On the skylight panels, a thinner metal was used with a custom forming technique to obtain the sharp angle required. Each fabrication step had its own custom QC process held to extremely tight tolerances to ensure all parts would fit together as expected. After QC’ing all parts, everything was protected with masking for shipping and installation and only removed at completion. Getting the oversized Muntz panels into the upper floors of the building required an orchestrated logistics effort including the use of a crane to elevate crates onto the 12th floor balcony. Once in the building, the Muntz panels were installed using custom tools designed and manufactured by Eventscape specifically for this application. The tools ensured a safe and efficient working environment so that the Muntz panels would not get damaged during handling. Eventscape coordinated with the GC to implement a scaffold spanning the atrium that would be safe; allowing the installation of panels overhanging the slab and other trades to complete their work simultaneously. The custom guardrail was extruded out of aluminum and engineered to have precise angles as required by the client. After cutting and polishing an anodized finish was used.

During installation, the powder-coated steel framing was installed first. Each frame was unique to its location to create a graduated elevation, reaching the ceiling in sections and dropping down to handrail height in others. These were welded to steel embedment plates cast-in to the concrete floor. Once these frames were secure, the Muntz panels were installed with custom stained and finished solid walnut caps. Even the hardware was a custom brass finish to pair with the Muntz metal. The installation team used lasers to maintain the vertical alignment across this diagonal space for all panels. Working on 7 floors simultaneously required both precise logistics and a detailed phased schedule. This stunning project won the 2020 Interior Design Magazine BOY (Best of Year) award for Finance/Law Offices.

Testimonial from Architect:

“We have seen the first class work of Eventscape through our collaboration on the Law Office in Washington, DC and the Rocket Mortgage FieldHouse in Cleveland, as well as multiple projects in design around the country and in Canada. The value that Eventscape is able to bring to the design and construction process is without question. One of the things we love about how they work is that they’re material agnostic—most fabricators prefer particular materials and will push their use regardless of the desired performance or aesthetic for the project. Everyone at Eventscape is interested in getting the best product without being afraid to offer a suggestion that will get the team there.

For the interior screen wall lining the eight-story diagonal atrium at the law office, dubbed the “Sleeve”, Eventscape did everything in-house (engineering, metal cutting/bending, wood milling, etc), working with a variety of materials (solid wood, veneer, muntz, brass fittings, structural steel, etc). Touring their facilities was also a designer’s dream as the fabrication spaces are all meticulous, showing the care everyone at Eventscape takes with their work. Every component of the Sleeve fit seamlessly and the final product realized the ambition and grandeur of the original design.

The entire Eventscape crew, from sales and marketing to design delegation and engineering to fabrication and installation are incredible to work with. They are able to understand intent regardless of the level of development of the design when they are brought on board. Whether a napkin sketch or full Construction Documents, they are ready to jump in and offer their expertise.”

Andrew Daley AIA, Senior Associate, SHoP Architects

Testimonial from client:

“Eventscape was commissioned to engineer, fabricate and install a custom metal screen spanning 8 floors. Eventscape distinguished itself from beginning to end on the project, through utmost professionalism and craftsmanship. That professionalism permeated throughout the entire organization and made working with everyone a very positive experience.

While the project was highly complex, Eventscape never missed a deadline. The design team was incredibly easy to work with, taking our feedback on early mockups and translating the suggestions into beautiful work. All deliverables were produced when promised. Their on-site team was exceptional, working long hours to ensure that their part of the project remained on track.

In an industry where delivering high quality product on time and on budget can be a challenge, Eventscape truly stands out. I wouldn’t hesitate recommending them to anyone and would work with them again in the future, should the opportunity present itself.”

“ Your team was fantastic and your head installer on site was the best. Anyone who’s toured the space has heard me praise Eventscape – the quality of the workmanship, engineering and ease of working together.“

Senior Director of Administration, Confidential Law office