PROJECT TIFFANY & CO., YORKDALE MALL, TORONTO, ON

DESIGN TIFFANY & CO GLOBAL REAL ESTATE STORE DEVELOPMENT

GENERAL CONTRACTOR STRUCTURE CORP.

ARCHITECT STEVE E. BLATZ ARCHITECT

BUILT BY EVENTSCAPE, DECEMBER 2014

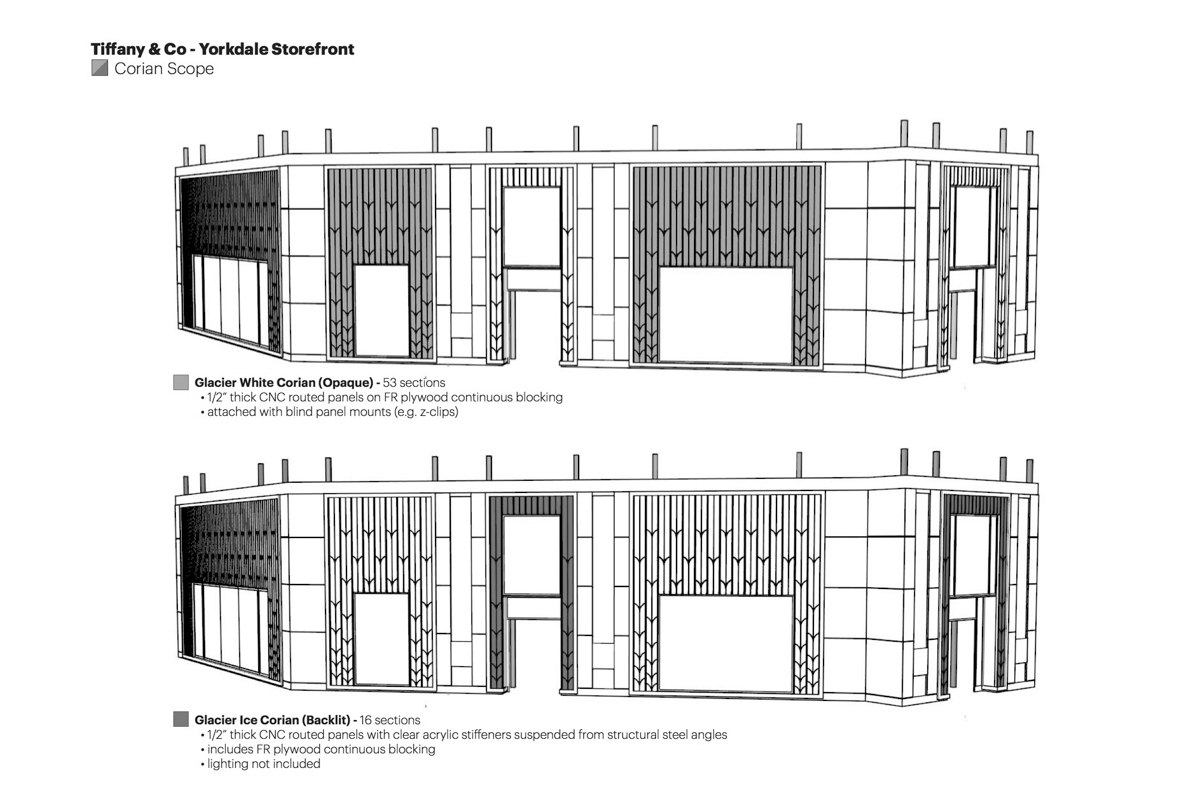

An impressive 24-foot high storefront cladding in pure white milled Corian creates a classic, elegant face for the renovation of the Tiffany store at Yorkdale Shopping Centre. The design references the Art Deco styled entrance to the flagship store on 5th Avenue in NYC. The classic wheat leaf pattern used on the walls represents nature, which is an important inspiration of Tiffany design. Previously this iconic pattern has been created from carved glass, marble and stainless steel in other stores but this is the first time Tiffany has used a solid surface material.

Unique Characteristics & Project Challenges:

Both interior and exterior renovations of this store were conducted simultaneously, with construction taking place in the evenings so that the store could remain open for business. Eventscape’s scope on this project was the Corian façade, CNC milled with the wheat leaf pattern. Three of the walls used 1200 square feet of opaque white Corian and 175 square feet of white backlit Corian highlight the two entrance walls. These 1/2” thick panels were framed by a 5 1/2” wide 16 gauge aluminum trim, powder coated white. Lacquered MDF panels and etched glass lit with blue lighting by others finish off the walls.

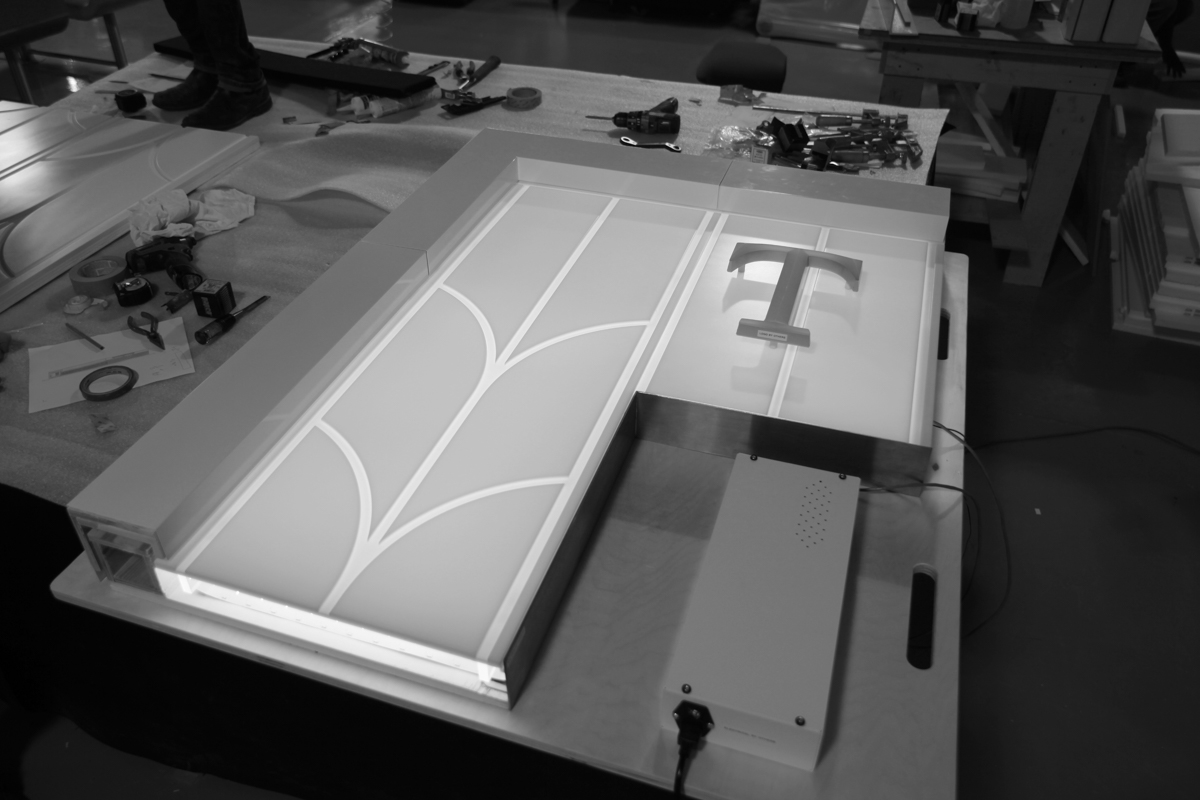

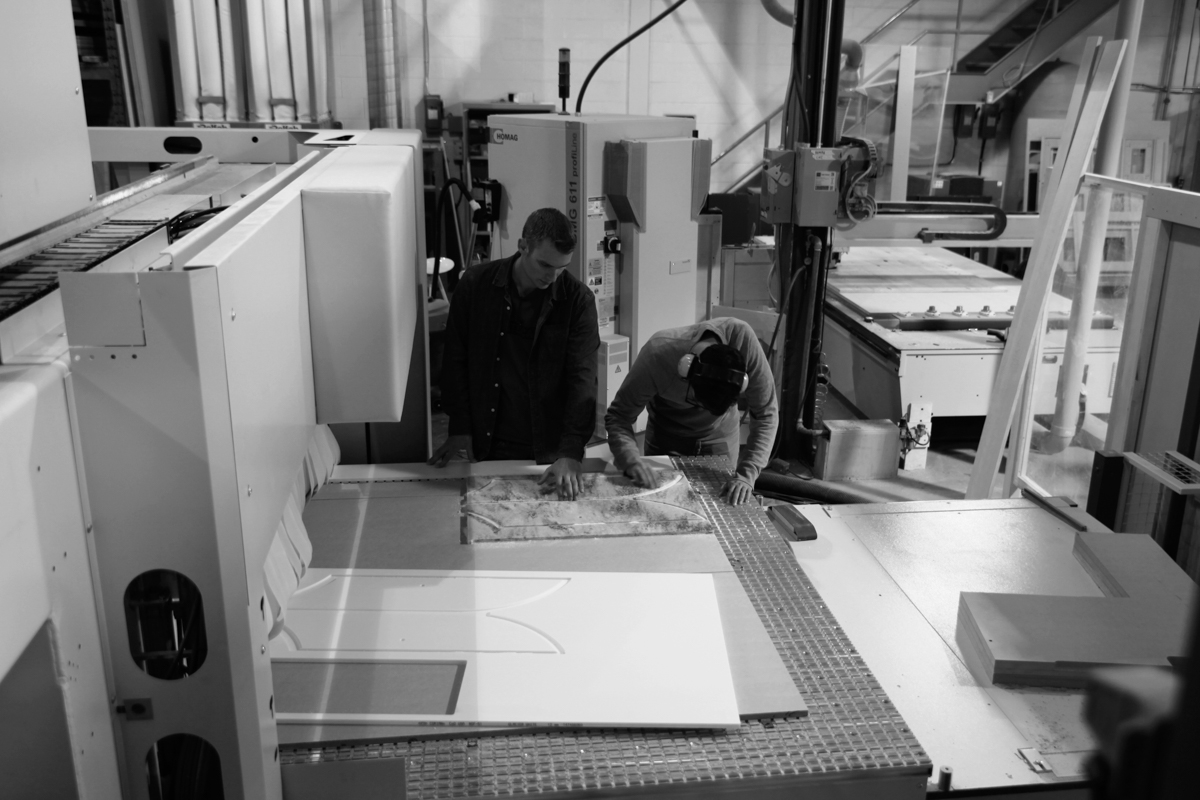

Eventscape has several years of experience with Corian fabrication. For the initial mockup, the Eventscape team worked closely with the lighting designer, researching placement and material selection for the signage and standoffs on the backlit to prevent shadows. Each of the walls were a different overall width so all Corian panels were cut to fit without changing the scale of the wheat leaf pattern from one area to the next. After first milling the panels on the 5 Axis CNC machine, they were then glued together. All but the header panels required at least one seam because of the 12-foot raw material limit in sheet size. The seams were skillfully created in the center of the milled pattern, and then glued and clamped using a custom metal jig so that the finished panels appeared seamless. After gluing the sections together, the panels were sanded, buffed to a high degree of sheen and cleaned before they were packed in custom crates. Since the install location was local, Eventscape was able to re-use the crates over the 6-week timeline.

The backlit panels required a clear acrylic standoff backer that also acted as a stiffener to disperse the weight over the 24-foot length. The opaque panels used a plywood backer and clipping system for attachment to the substructure provided by the general contractor. All custom designed channel hardware attachments were engineered to carry the load of the 4.4 lbs per square foot Corian.

Maneuvering of equipment and material on site was challenging during installation as the hoarding was ceiling height and only 8 feet away from the storefront. Tolerance was only 1/16” so detailed coordination was crucial with the other trades so that all materials aligned on site. Installation was completed in time for the Black Friday opening.