PROJECT “BORN AND RAISED” SNOWMEN SCULPTURES

DESIGN STUDIO HOW-TO-SEE

ART CONSULTANTS PUBLIC ART MANAGEMENT

GENERAL CONTRACTOR PCL

PHOTOGRAPHY EVENTSCAPE INC.

BUILT BY EVENTSCAPE JULY, 2018

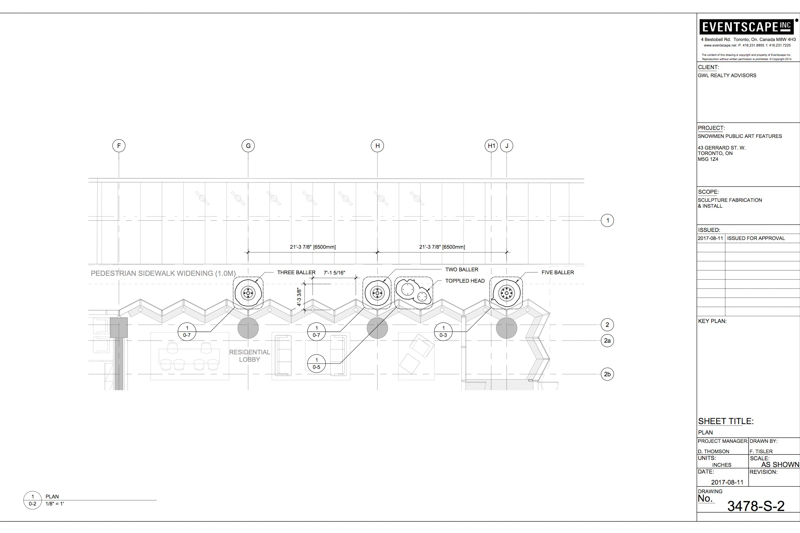

A series of playful, oversized white snowmen complete with hats and carrot noses grace the exterior of The Livmore, a new 43-story apartment building in Toronto. Called “Born and Raised”, the sculptures are nestled close to the building next to the sawtooth-pattern lobby windows. Built of fiberglass with steel rod center cores, this public art “snow” sculpture won’t melt even in the hottest summer weather!

Eventscape was contracted to engineer, fabricate and install all 4 sculpture elements. There are 3 “snowmen” all made out of “heads” with various expressions and torsos. The largest of the snowmen, with five spheres, stands 17-feet tall. The two others were built with 3 spheres each, but one of the sculptures has its head and toque on the ground as if it has toppled off.

Unique Characteristics & Project Challenges:

The original 3D mesh file received from the artist was transformed into a digital scale model by Eventscape’s designers. The model was further broken down into machinable sections to be milled on the 5-axis CNC machine. Three to four sections per sphere were created from high density milling foam. These sections were glued together and a 1/4” layer of color-tinted fiberglass applied over the top. The milling of the form was done slightly deeper to accommodate the fiberglass which could have smoothed out the organic quality of the form. A 2-part epoxy finish coating was applied for consistent color, UV protection and durability.

Each sculpture had a steel HSS center core. Galvanized steel mounting flanges were fiberglassed into each sphere which were secured onto the center core. The 5-sphere, 3-sphere and 2-sphere sculptures were fabricated as consolidated towers for ease of installation and to hide any steel hardware. At the base of each sculpture, an access panel was incorporated where the integrated custom laser-cut steel bracket attached to the on-site concrete “piers” supplied by the general contractor. The piers neatly tucked up inside the bottom sphere to create a small reveal between the base and concrete sidewalk.

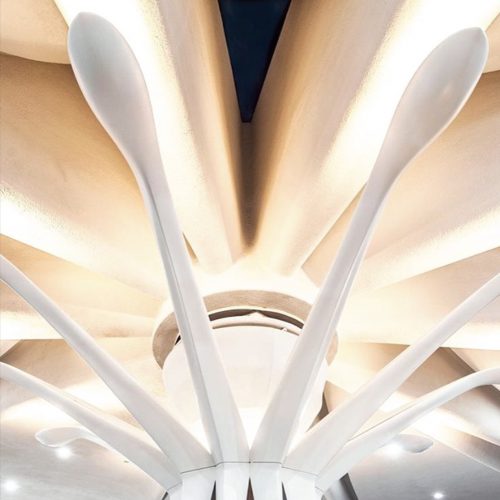

The black hat was built with the same processes as the spheres. A ribbing detail was used in the brim and roving was added to the fiberglass to create the appearance of fabric. A steel lifting hook at the top of each sculpture was ultimately concealed by the hat, which attached to the head with a threaded rod.

The carrot was one of the most interesting parts to build. The artist wanted a realistic looking carrot so the Eventscape project manager scoured the stores to find the largest carrot she could that had the desired shape. The carrot was 3D scanned and enlarged in scale to create a 3D print. This was then used to create a silicone mold. Different densities of rubber were mocked up to determine the strength required to prevent breakage but not be a dangerous protrusion on a public sculpture. The rubber was color-tinted to achieve the right shade of orange and poured into the mold with a center threaded rod. The end of the carrot was modified to create a perfect circle to could freely rotate within the nose cavity where the rod was secured to the steel coupling.

The installation was challenging as the weight of the sculptures and the large diameter left little opportunity to find secure grips. This exterior public art sculpture was structurally engineered for stability and safety. The geometry and slope of the eye and mouth openings were adjusted during the design phase to prevent water from pooling and to prevent the public from climbing the sculptures.