PROJECT GTAA PASSENGER INFORMATION ZONE, PEARSON INTERNATIONAL AIRPORT, TORONTO ON

DESIGN STANTEC

GENERAL CONTRACTOR ROYALTY GENERAL CONSTRUCTION

PHOTOGRAPHY STEVE TSAI

BUILT BY EVENTSCAPE, OCTOBER 2016

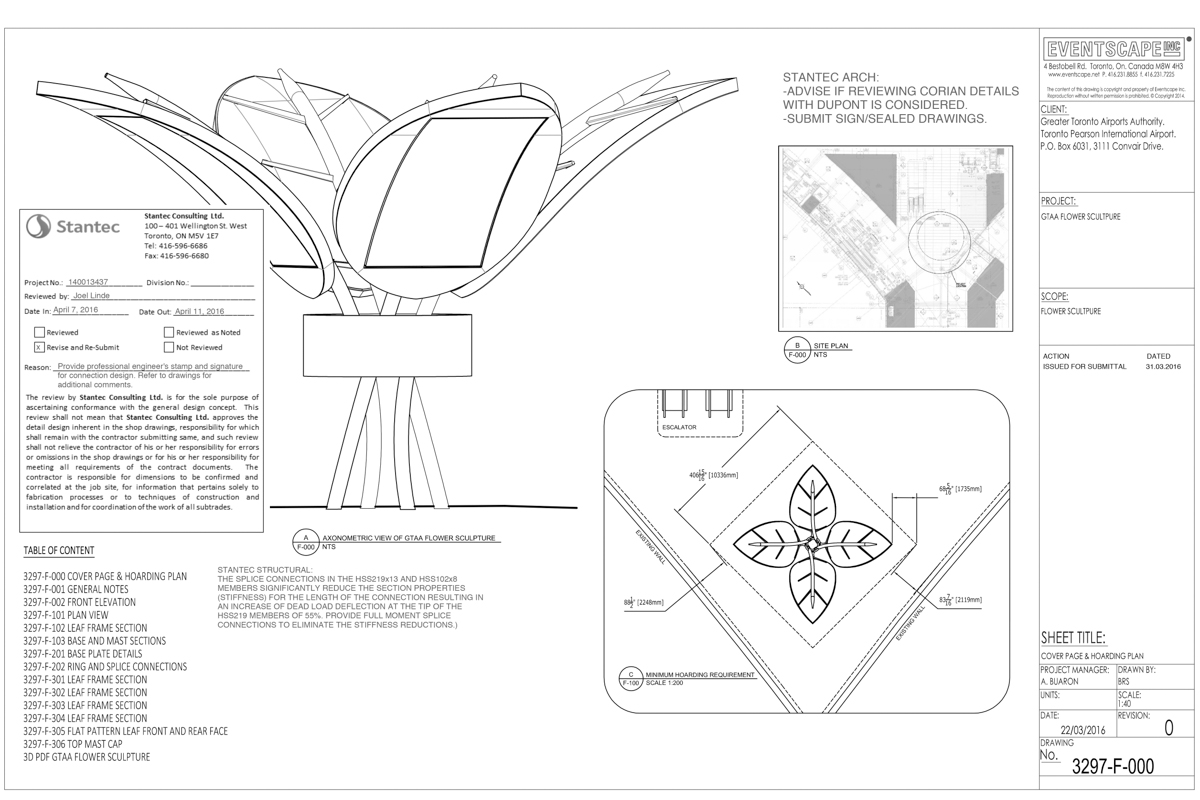

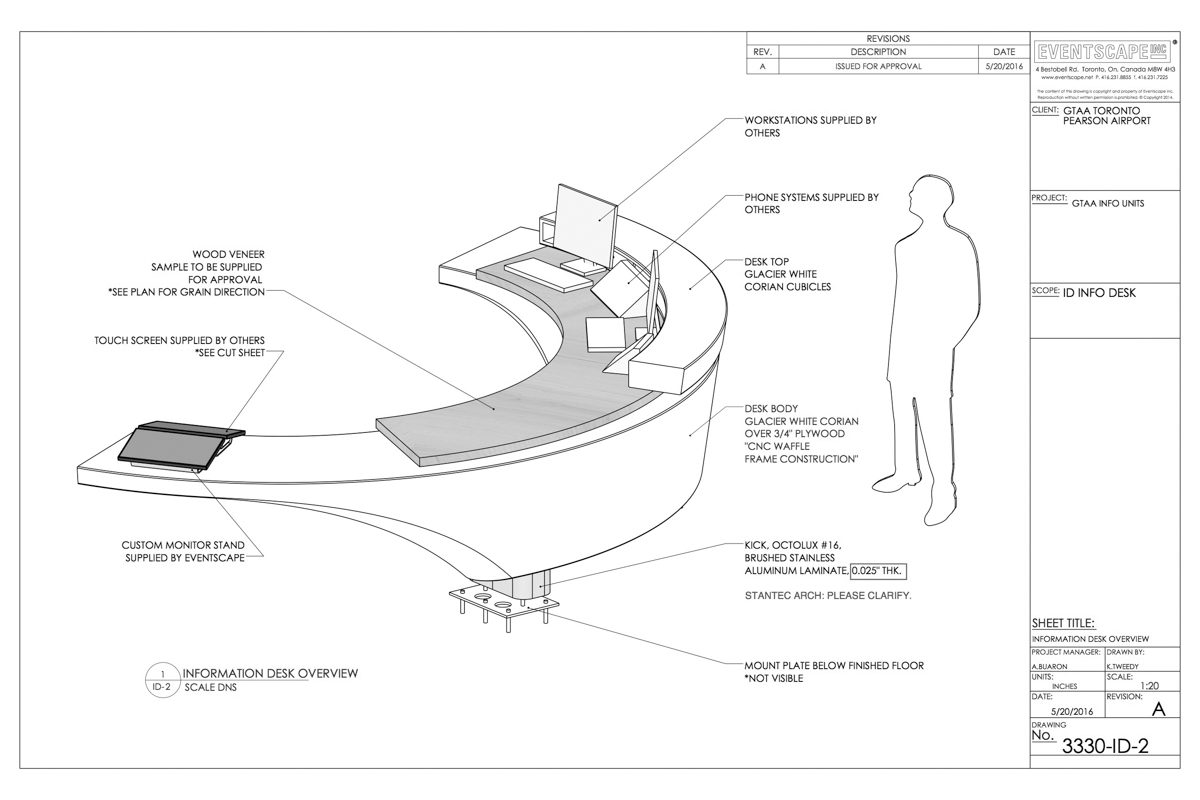

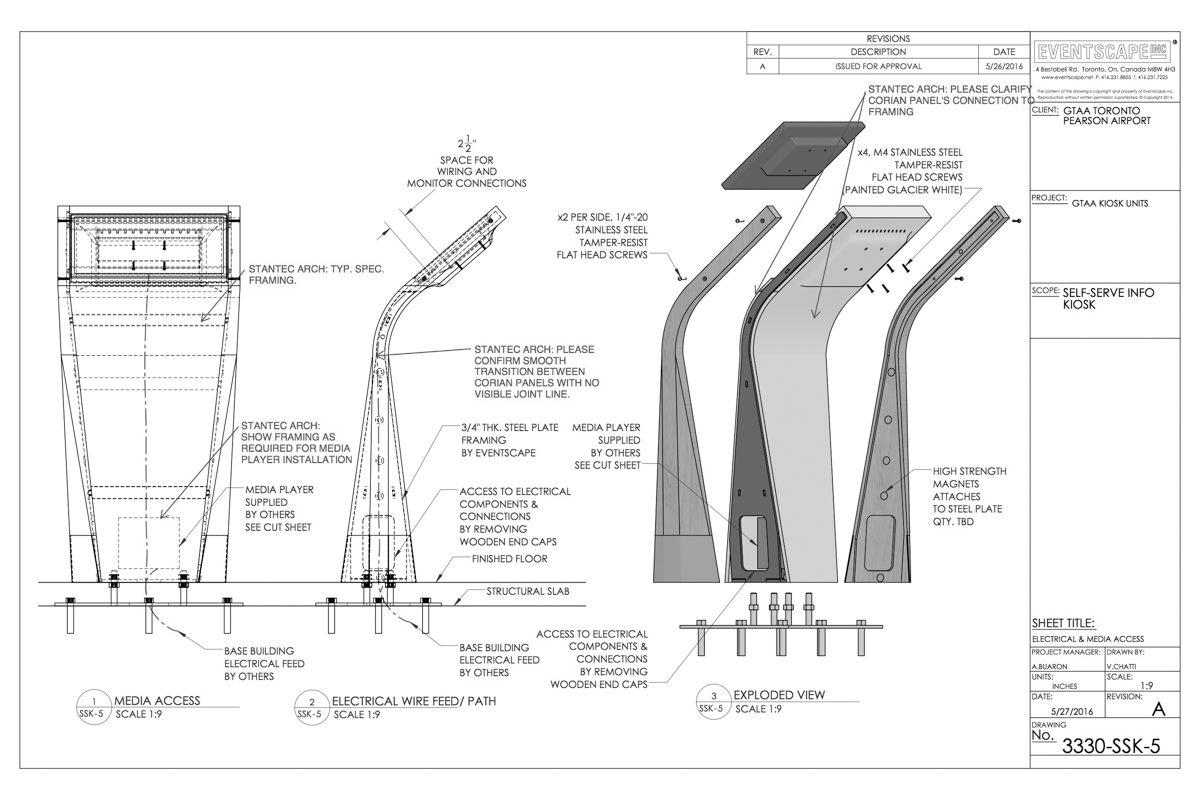

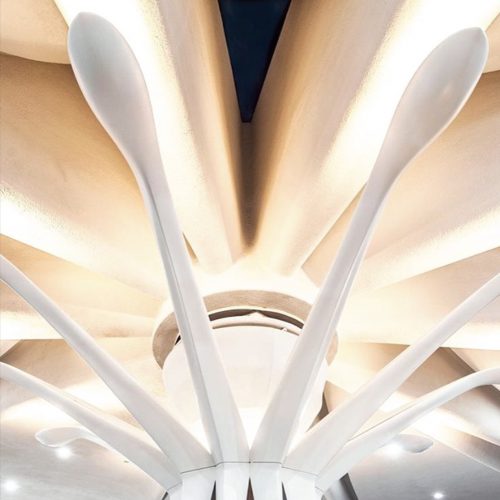

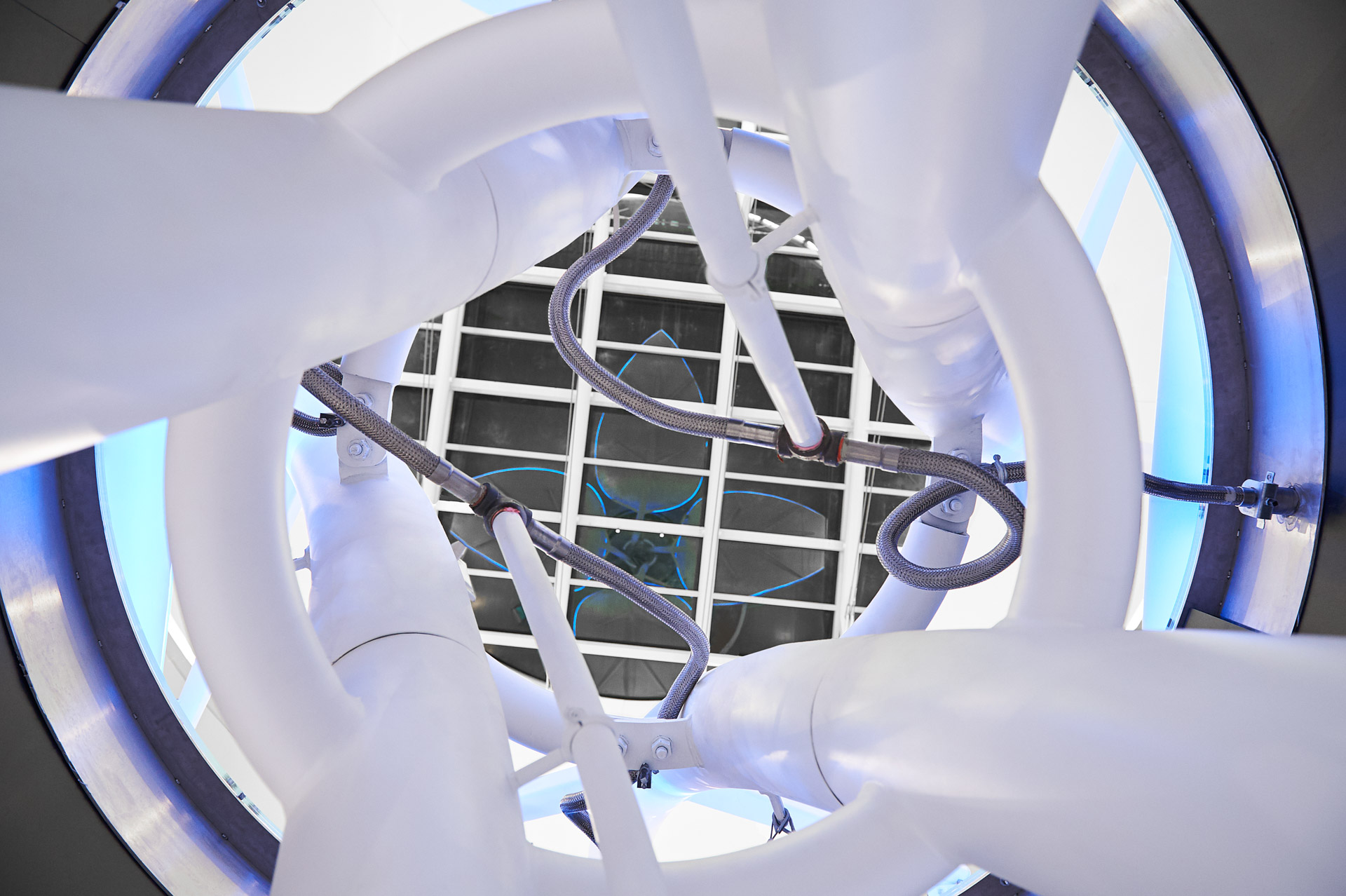

A massive 25-foot tall steel and solid surface sculptural flower structure with 4 “petals” makes a dynamic centerpiece to this information area in Terminal One. The backlit solid surface petals each hold a 12-foot by 5-foot wide LCD screen, which show the latest travel information. Surrounding the sculpture is a circular information desk with integrated monitors, solid surface and solid wood top and stainless steel accents. A curved steel frame on the desk supports the 2 cantilevered sections clad with a double curved solid surface skin.

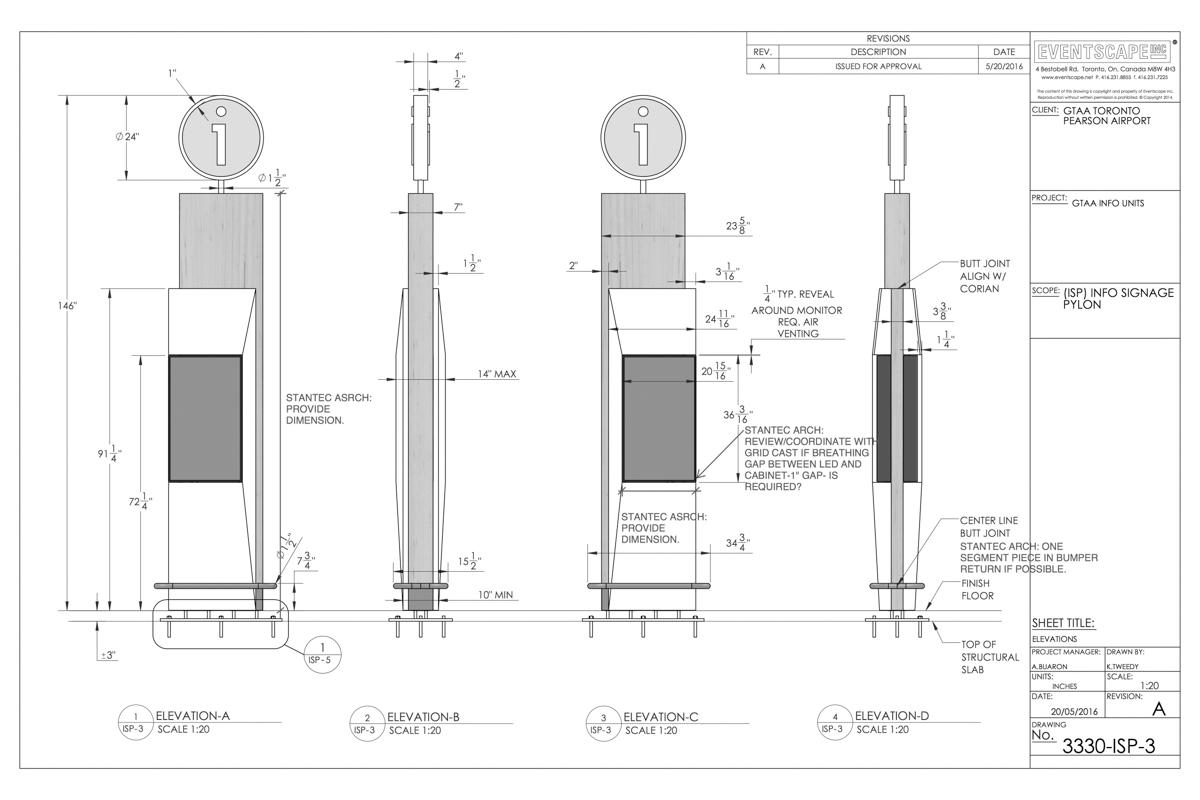

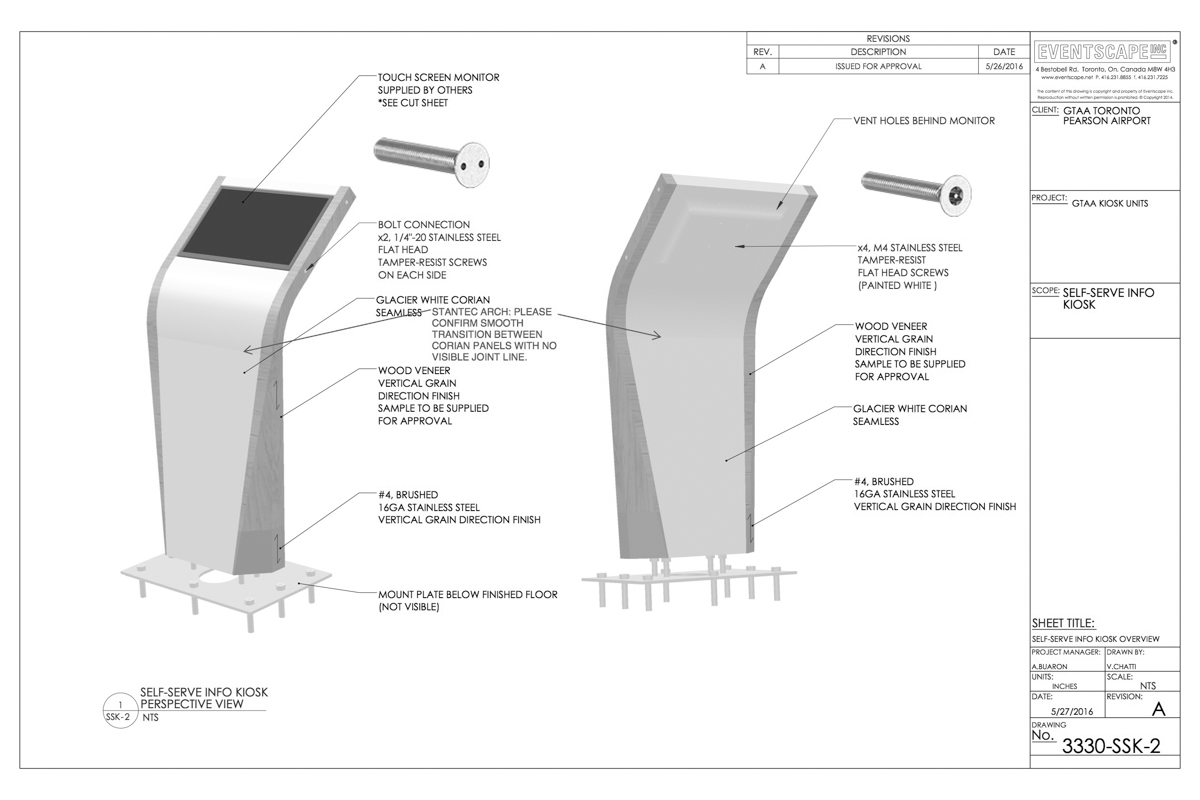

A 12-foot high information pylon and six stand alone kiosks with LCD screens, solid surface and wood veneer finish encircle the sculpture. The second stage of this project is an additional 18 kiosks in two different sizes, 6 pylons and 3 smaller information desks situated in various locations throughout the airport.

Unique Characteristics & Project Challenges:

Flower Sculpture: The central “flower” sculpture went into production first while design development continued on the desk, pylons and kiosks. The main challenge with the flower structure was engineering the helical pattern of the 8” diameter, 1/2” thick structural steel stems. Each of the four stems intertwined and curved outward, requiring an engineered support system. A 4” diameter steel ring was engineered to support the helix shape at the mid-section and transfer the load down to the floor, where the legs connected to individual I-beams in the slab. Each of the stems had a structural splice mid-way so that the 30-foot long stems could be delivered and joined on site. Concealed with a sleeve connection, the structural splice resists simultaneous bi-axial moments, bi-axial shear forces, and axial force. A second tension ring was first welded and then mechanically fastened on site to the adjacent stem with bolt connections. Connection points were finished with rolled powder coated steel cover sleeves for a smooth finish. A LED halo covers the two centre connecting rings of the stems and shows current weather with seasonal themes.

Several milled circles were part of the design of the solid surface finish on the petals, so a mock up section was fabricated to determine the optimum milling depth and light placement for a consistent glow and the best shadow effect. The petals were built with a structural steel tubular frame, milled solid surface face and a fully removable back for maintenance access. The frame was attached to the upper stem and all wiring for lighting and LED monitor (by others) was fed through the stems.

Information Desk: The 22-foot long main information desk was challenging to engineer and fabricate, as it was a cantilevered shape. The digital design/fabrication team used a combination of solid and thermoformed solid surface over a wood sub frame with an engineered structural steel support. Underneath the top laser cut steel plate, a 5” x 5”rolled formed structural steel tube spine connected to the vertical steel tubes. At the floor, the feet connected to a steel base plate anchored to the structural concrete slab. Wiring for data and power were fed up through the tubes from the floor below. The solid surface was sanded and polished smooth to create the graceful arc of the cantilevered desk edges. The desk included several lockable drawers and storage cupboards. Phase two of this project will be a number of additional smaller desks throughout the airport.

Pylon: The 12-foot high x 2-foot wide information pylon incorporates an interactive touch display of flight information for passengers to browse, along with a map of the airport. The 2-foot high LED backlit “i” at the top of the pylon directs visitors to this zone. The pylon was built with a structural steel metal frame, wood veneer, angled solid surface finish and anchored to the structural slab below. A stainless steel bumper rail completed the bottom of the structure.

Kiosks: Similar in construction to the desk and pylon, with steel sub frame and wood and solid surface finish, the self-serve information kiosks are gently curved to give the perfect viewing angle for the integrated touch-screen monitor. Surrounding the central flower sculpture and desk, there are 6 kiosks – 5 at standing height and one lower height, ADA compliant. A vacuum-formed solid surface back panel with ventilation holes houses the monitor. Security fasteners were used for assembly to allow access for maintenance. The wood end caps had a complicated geometric shape that was both curved and faceted. The digital fabrication team at Eventscape used CNC-cut high density tooling foam as the base and added carefully applied wood veneer laminate. After staining, a catalyzed lacquer sealer was applied to give an extremely durable finish for this high traffic area.

Phase Two of this project will include additional smaller information desks, multiple self-service kiosks and interactive pylons throughout the airport creating numerous passenger information zones.