PROJECT MALL OF AMERICA – STAR LOGO FEATURE, BLOOMINGTON, MN

GENERAL CONTRACTOR M.A. MORTENSEN CO.

BUILT BY EVENTSCAPE, JULY 2015

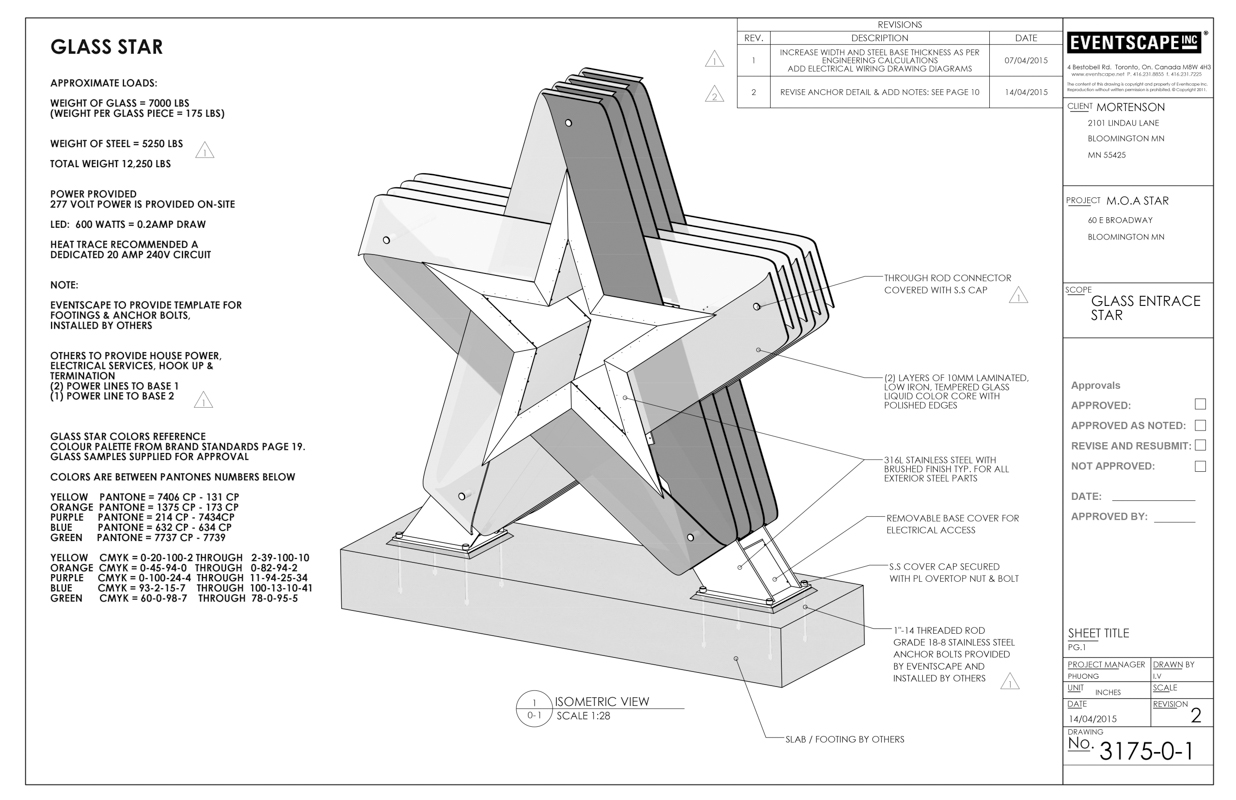

A 4-layer 12,000 lb. exterior glass star is a striking 3 dimensional representation of the new updated Mall of America iconic star logo. The 3/4” thick laminated colored glass sections all match the MOA brand standards and include white LED lighting. Built of a stainless steel frame with hidden access panels in the 1” thick stainless steel legs, it is anchored to a concrete slab base and stands over 16 feet high and 16 feet wide. It also incorporates a sensor activated heat trace to melt any snow or ice immediately. Mall of America is currently undergoing an 750,000 square foot expansion with the addition of specialty retailers, dining experience, office tower, luxury hotel and a grand entrance. Surrounded by landscaping and the VIP valet driveway, the star is a dynamic feature centerpiece to this grand entrance.

Unique Characteristics & Project Challenges:

As Mall of America worked with Eventscape on a previous custom project and were aware of the company’s capabilities, they approached the team very early in the process, in 2012, to discuss their ideas for the new expansion project. The goal was to create a dynamic sculptural feature of their newly revamped star logo, as the focus of the new VIP entrance to the high-end retail expansion

Initially Mall of America desired a folded stainless steel ribbon look but later, revised it to colored glass.Eventscape designed several concepts for the fabrication of the glass star; with 2, 3 or 4 layer options. Once the decision was made to go with the 4 layer glass star, colors were chosen for the glass to match Mall of America brand standards and a series of samples were created for approval. To obtain the best color match for their brand standards, Eventscape used two layers of a 10 mm clear low iron tempered glass, laminated together with an interlayer of custom colors. The Eventscape fabrication team built a custom wood jig so that the stainless steel shoe for each was placed accurately. These shoes then fastened to the interior structure and secured with custom stainless steel standoffs. A stainless steel fascia finished the front and back faces.

The interior structure of the star was fabricated using an high-grade brushed 316L stainless steel. The legs required a thicker 1” stainless steel to obtain the necessary engineered support, while 1/2” and 1/4” stainless steel was used in the rest of the structure. To ensure the correct geometry for the star, a full one-to-one size plywood mockup was built. All elements of steel and glass were then fitted matching this mockup. To access the lights and electrical connections for the heat trace, an access panel was designed with no visible hardware. 70% of the hardware was custom machined from stainless steel. Since the majority of the hardware was visible, each piece was designed with a beautiful clean profile and finish.

Great care was taken in the handling and assembly of the glass elements. For shipping, custom crates were built to accommodate each panel, cushioned and securely fastened with bolts inside the crates. As each panel weighed 175 lbs, the fabrication team used the hydraulic lift to move the panels into place. A custom jig was engineered and fabricated to lift the steel interior structure from the shop floor onto a “low boy” trailer for shipping. Eventscape’s logistics team established a dedicated truck route with sufficient height passages and utilized a pilot car so that the 16 foot high structure had a clear route.

The glass panels were shipped separately in a second shipment which arrived simultaneously on site in Bloomington. The installation team used a crane to carefully lift the stainless steel interior structure off the truck and lower it onto the concrete pad on site, matching up perfectly to concrete anchor rods and electrical conduits. The alignment coordination was managed using a template provided by Eventscape. Each glass panel was supported by a boom lift using a cantilevered clamp, so that the mobile crane could maneuver each one onto the structure in sequence, and attached by hand using the custom stainless steel hardware. Later, landscaping was added to the surrounding garden and the first phase of the new expansion opened to the public at the beginning of November.